Industrial pumps are used in farms, factories, and buildings. They help move water or other liquids. But sometimes, they stop working. That can cause a big mess. If a pump breaks, work stops, and that wastes time and money. Pumps can leak, make weird sounds, or get too hot. But you can stop those problems early if you know what to look for.

Too Much Heat Can Hurt the Pump

Many industrial water pump systems get too hot when used for a long time. This is called overheating. It happens when the pump runs without water or insufficient air around it. The pump gets hotter and hotter, damaging the motor and other inside parts. To stop this problem, give the pump time to cool down. Let it rest between uses. Keep it clean and make sure nothing is blocking the air.

Leaky Seals Can Make Big Trouble

Seals are small parts that stop water from leaking out of the pump. In industrial sump pump machines, these seals can wear out fast. When a seal breaks, water can leak into the motor or wires. This can cause a lot of damage. Leaks may be small initially, but they can grow bigger over time. To stop this problem, check the seals often. Look for cracks or signs of wear. Use strong, good-quality seals. If you see a lousy seal, replace it right away. is better than fixing big damage later.

Clogs Slow Everything Down

Clogs happen when dirt, trash, or thick sludge gets inside the pump. In filter pump industries, this is a common problem. A clogged pump has to work harder to move water. This makes the pump hot and weak. It may even stop working.

Air Bubbles Can Break the Pump

Sometimes, when a pump does not have enough water, bubbles form inside. This is called cavitation. These bubbles pop and hit the pump's parts very hard. That can break the parts inside. Cavitation is terrible for industrial centrifugal pumps and other Industrial pumps. To stop it, always ensure enough water before starting the pump.

Motors Can Burn Out

The motor is the part of the pump that makes it run. The motor can stop working in industrial vacuum pump setups if it gets too hot or if there is insufficient power. Old motors can also stop working. This is called burning out. If this happens, the whole pump stops. To protect the motor, use power protectors.

Bearings Need Oil to Work Right

Bearings are round parts that help the pump spin smoothly. In water pump industrial systems, bearings can go bad if they do not have oil. Dry bearings make loud noises and can break quickly. This can stop the whole pump from spinning. To prevent this, add oil or grease often. If the bearings shake or make noise, it means they need help. Clean them and check for dirt. If they are broken, change them. Smooth bearings help the pump work quietly and last longer.

Rust Can Ruin the Pump

Rust happens when water stays on metal parts too long. Rust eats the metal and makes holes. This can lead to leaks and damage. Rust is a big problem in industrial heat pump systems, especially in wet places. To stop rust, dry the pump after each use. Wipe off all the water with a cloth. Store the pump in a dry spot.

Bad Setup Can Break the Pump Fast

A pump can break very quickly if it is not set up correctly. Parts may be loose or not lined up right. This can make the pump shake, leak, or make loud sounds. To stop this, follow the setup guide carefully. Make sure every part is tight and in the right place. If you are not sure what to do, ask someone who knows. A good setup helps the pump run better and stay safe. A bad setup can cause problems again and again.

Simple Ways to Keep Your Pump Working

Pumps are used in small jobs and big jobs. Some work in homes. Others work in filter pump industries or with big industrial centrifugal pumps. No matter the size, every pump needs care. Always keep the pump clean. Look for leaks, dirt, or damage. Oil the parts that move. Make sure the power is good. Let the pump rest sometimes.

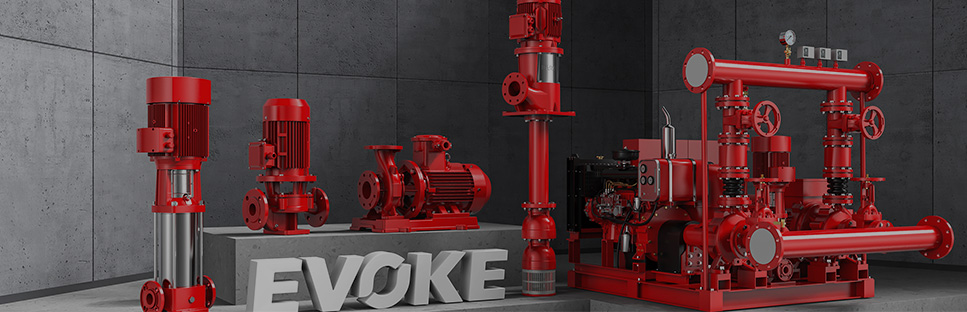

Best Place to Buy Industrial Pumps

Need a strong pump that lasts? EVOKE Pump has what you need! They sell high-quality pumps that are powerful and affordable. Their website is easy to use, and they have great prices. They have many choices if you need a pump for a factory, farm, or water system. Visit www.evpump.com today and order now!

Top Industrial Pumps

ES End Suction Centrifugal Pump – Moves water fast and smooth. Easy to use and great for oil and water transfer.

EPV Vertical pipeline pump – Small, space-saving, and stands upright. Runs quiet and works well in tight spaces.

ESC Double Suction Split Case Pump – Built for big jobs. Runs long hours without stopping. Strong and safe for industrial use.

To keep Industrial pumps running, check them often. Listen for strange noises. Look for leaks. Clean the pump and fix minor problems fast. Replacing bad parts early helps the pump last longer. Take care of it, and it will work well.